Manufacturing and supply chain management consulting

We help manufacturing and supply chain companies solve complex problems and optimize their operations to drive efficiency, reduce costs, mitigate risks, and achieve sustainable growth.

Manufacturing & Supply Chain

Unlocking supply chain excellence

We’re proud to serve diverse businesses in the Manufacturing & Supply Chain sector, implementing custom solutions for clients across various industries, including:

- Aerospace & Defense

- Automotive

- Agriculture

- Chemical and Process

- Electronics

- Industrial Distribution

- Industrial Products

- Paper, Metal, and Rolled Products

- Textile & Apparel

We specialize in solving industrial and manufacturing challenges through our industry, people, and technology expertise. Our consultants specialize in supply chain optimization, enhancing efficiency, reducing waste, and improving quality across warehouse management, process improvement, inventory optimization, business recovery, and more.

Our services include:

Program Management

Deliver your complex, strategic initiatives with experienced program managers who can manage risks and deliver programs.

Supply Chain Recovery

Recover from bad ERP implementations, staffing turnover, supply chain disruptions, and more.

Warehouse, Distribution Center, & Inventory Optimization

Improve efficiency, reduce costs, and reduce inventory levels while having the right parts on hand at the right time.

CASE STUDY

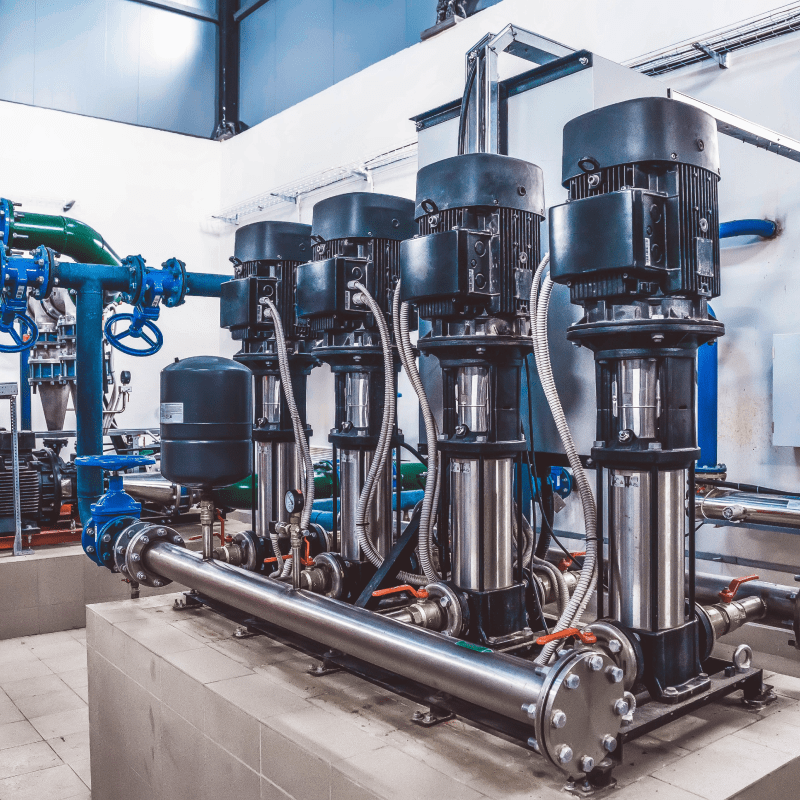

Industrial Pump Manufacturer: Inventory Optimization

.jpg?width=600&height=600&name=AdobeStock_595871888(1).jpg)

The Problem

An industrial pump manufacturer had major global supply chain, inventory, and on-time delivery issues that were severely impacting operations and customer satisfaction.

Our Solution

We utilized our rapid value attainment TM methodology to identify opportunities for improvement, then planned and executed two 12-week recovery sprints.

Results

- 95% decrease in part outages

- 75% increase in on-time delivery

- 17% reduction in on-hand inventory

CASE STUDY

Small Appliance Manufacturer: Supply Chain Performance

.jpg?width=600&height=600&name=AdobeStock_595871888(1).jpg)

The Problem

Poor supply chain performance limited production for a small appliance manufacturer, impacting warehouse operations and demand planning and forecasting.

Our Solution

We utilized our rapid value attainment TM methodology to identify opportunities for improvement, then planned and executed three 12-week recovery sprints.

Results

- 50% reduction in production planner time

- Forecast generation time reduced from 3 weeks to 4 days

- 66% increase in outbound warehouse picking efficiency

CASE STUDY

Orthopedic Device Manufacturer: BOM Errors Resulting in Significant Financial Variance

.jpg?width=600&height=600&name=AdobeStock_595871888(1).jpg)

The Problem

A manufacturing site of a global orthopedic device manufacturer had BOM errors on more than 20,000 parts and material flow issues, resulting in significant financial variances and excess inventory.

Our Solution

Within just a few weeks, AXIA performed an assessment, determined the root cause, and quickly fixed the BOM errors and the materials factory flows.

Results

- 254% increase in inventory accuracy

- Reduced WIP from 15.3M to 6.3M

- Reduced errored production jobs from 100% to < 3% of jobs

CASE STUDY

Global Health and Fitness Manufacturer and Distributor: Packaging Efficiencies and Transportation Analytics

.jpg?width=600&height=600&name=AdobeStock_595871888(1).jpg)

The Problem

A health and fitness manufacturer and distributor was experiencing high packaging and transportation costs.

Our Solution

AXIA performed an analysis of over 1.6M small package freight shipments to identify opportunities for improvement. We guided the organization through the implementation of advanced packaging systems to provide “right-sized” packaging and eliminate waste, and identified over $1M+ in transportation cost savings opportunities.

Results

- Cost savings with multimodal selection via LTL and small parcel

- Improved packaging efficiencies

- Increased freight recovery rate

- Reduced accessorial charges

CASE STUDY

Industrial Pump Manufacturer: Inventory Optimization

The Problem

An industrial pump manufacturer had major global supply chain, inventory, and on-time delivery issues that were severely impacting operations and customer satisfaction.

Our Solution

We utilized our Rapid Value AttainmentTM methodology to identify opportunities for improvement, then planned and executed two 12-week recovery sprints.

The Results

- 95% decrease in part outages

- 75% increase in on-time delivery

- 17% reduction in on-hand inventory

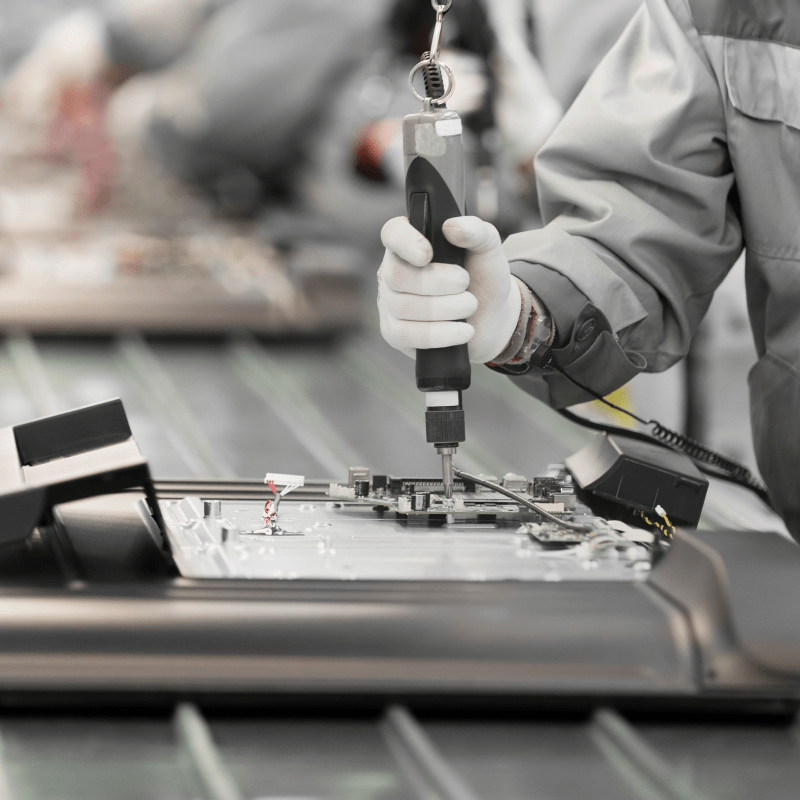

CASE STUDY

Small Appliance Manufacturer: Supply Chain Performance

The Problem

Poor supply chain performance limited production for a small appliance manufacturer, impacting warehouse operations and demand planning and forecasting.

Our Solution

We utilized our rapid value attainment TM methodology to identify opportunities for improvement, then planned and executed three 12-week recovery sprints.

The Results

- 50% reduction in production planner time

- Forecast generation time reduced from 3 weeks to 4 days

- 66% increase in outbound warehouse picking efficiency

CASE STUDY

Orthopedic Device Manufacturer: BOM Errors Resulting in Significant Financial Variance

The Problem

A manufacturing site of a global orthopedic device manufacturer had BOM errors on more than 20,000 parts and material flow issues, resulting in significant financial variances and excess inventory.

Our Solution

Within just a few weeks, AXIA performed an assessment, determined the root cause, and quickly fixed the BOM errors and the materials factory flows.

The Results

- 254% increase in inventory accuracy

- Reduced WIP from 15.3M to 6.3M

- Reduced errored production jobs from 100% to < 3% of jobs

CASE STUDY

Global Health and Fitness Manufacturer and Distributor: Packaging Efficiencies and Transportation Analytics

The Problem

A health and fitness manufacturer and distributor was experiencing high packaging and transportation costs.

Our Solution

AXIA performed an analysis of over 1.6M small package freight shipments to identify opportunities for improvement. We guided the organization through the implementation of advanced packaging systems to provide “right-sized” packaging and eliminate waste, and identified over $1M+ in transportation cost savings opportunities.

The Results

- Cost savings with multimodal selection via LTL and small parcel

- Improved packaging efficiencies

- Increased freight recovery rate

- Reduced accessorial charges

Our experts

Cliff Wilson

Director, Business Consulting

John Tierney

Managing Director

Matt Hauser

Director, Oracle Practice

Walt Staudenmaier

Director, Oracle Enterprise AppsAXIA Insights

AXIA Insights

FEATURED RESOURCE

Donec sed odio dui. Morbi leo risus, porta ac consectetur at eros.

Donec ullamcorper nulla non metus auctor fringilla. Integer posuere erat a ante venenatis dapibus posuere velit aliquet. Maecenas sed diam eget risus varius blandit sit amet non.

CASE STUDY

Case study option 2

Cras mattis consectetur purus sit amet fermentum. Cras justo odio, dapibus ac facilisis in, egestas eget quam. Sed posuere consectetur est at lobortis.

60%

80%

6

90%

AXIA Insights